- Canning single and multi-blade belt scrapers

- Canning chevron belt scraper

- Canning V-Plough

- Tangential scraper

- Rockline® conveyor products

- Eliminator® conveyor products

Related parts

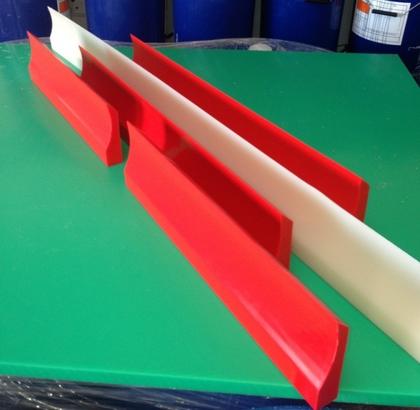

Tear Drop Replacement Blades

Generally known as Tear Drop Scraper replacement blades, these can be used for cleaning numerous belt width and gate end rollers.

Supplied in various hardnesses from 35 Shore A, through to 95 Shore A, and in various colours to meet customer requirements.

The maximum length available currently is 1300mm, but, if a longer scraper is required, new mouldings can be made in order to manufacture longer lengths

Secondary Brush Cleaner

- Totally new product designed to remove any excess material not removed by the primary blades

- Designed around the Series 2000 belt scraper it can be fitted from new or retro-fitted to existing units

- Can be used on chevron or flat belts

- Simple and easy to install, fully adjustable

Eliminator

Eliminator® provides special solutions for difficult belt conveyor problems.

The job of cleaning your belts especially those in tough, special applications can be done easily and safely with Eliminator Belt Cleaning Systems.

Eliminator offers a wide variety of pre-cleaners to match your requirements, or we can specially design a cleaner to meet your needs.

If belt mistracking is a problem the Flexco® PT MAX Belt Trainer is recommended.

Also transfer point spillage using the V-Plows and Flex-Lok Skirt Clamps feed boots at material feed points are available.

All your company needs to maintain top productivity on your belt conveyor applications.

Rockline

The Rockline® Belt Cleaner range has been engineered for simple, effective belt cleaning which is easy out-of-the-box installation, with minimal maintenance, budget conscious and affordable pricing.

Rockline® products are durable and dependable; you can count on their quality and value day in and day out.

With periodic parts replacement and occasional adjustments, Rockline® products deliver years of outstanding service.

Canning Plough

The V-Plough from CANNINGS ensures a clean return strand belt.

- V-formation removes material to both sides of belt

- Prevents materials from entering tail drum

- Long lasting 95 shore hardness polyurethane blade

- Reduces wear on belt, tail drum and take-up pulleys

- Improves belt tracking

- Simple installation

- Suitable for belt widths of 300mm – 2000mm

Canning Chevron

Type CB Chevron Belt Scraper

The first scraper to cover ALL chevron belt cleaning problems

- Unique “finger system” allows scraper to be fitted in any position from the snub drum backwards

- Does not require slack belt to operate

- Works successfully on belts with both vulcanised and clip joints

- Old and worn belts are not damaged by our system

- Also works on convex drums

- Standard polyurethane 7 finger blades in 80 shore hardness, very flexible and cleans whole width of belt

- Easy fitting, low cost maintenance and spares

Canning Flat Belt Finger Scraper

The first scraper to cover ALL belt cleaning problems

- Patented “finger system” allows scraper to be fitted in any position from the snub drum backwards

- Does not require slack belt to operate

- Works successfully on belts with both vulcanised and clip joints

- Old and worn belts are not damaged

- Also works on convex drums

- Standard carbide tip 5 finger blades, very flexible and cleans whole width of belt

- Easy fitting, low cost maintenance and spares

Canning Single Blade

Type SB Single Blade Scraper

- Efficient low cost, low maintenance scraper

- Easy to install and maintain

- Torsion mounted for self adjusting

- 95 shore hardness polyurethane blade

- All metal parts zinc plated for protection

Cleated Belt Scrapers

- Patented “finger system” allows scraper to be fitted in any position from the snub drum backwards

- Does not require slack belt to operate

- Works successfully on belts with both vulcanised and clip joints

- Old and worn belts are not damaged

- Stainless steel tipped blades can be used for harsher applications

- Standard 7 finger blades, very flexible and cleans whole width of belt

- Easy fitting, low cost maintenance and spares

Tangential Scrapers

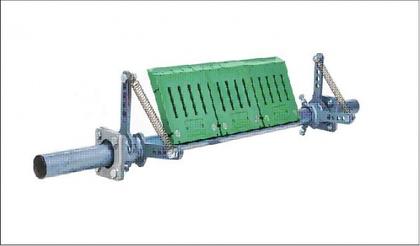

SERIES 2000 TANGENTIAL SPT

Flat Belt Scraper

- Patented finger design allows the blades to adapt to work on crown drums

- New constant spring tensioned design

- Tension mechanism can be mounted inside or outside the chute

- Can be fitted with carbide or non carbide blades

- Easy installation and low cost spares